SMT

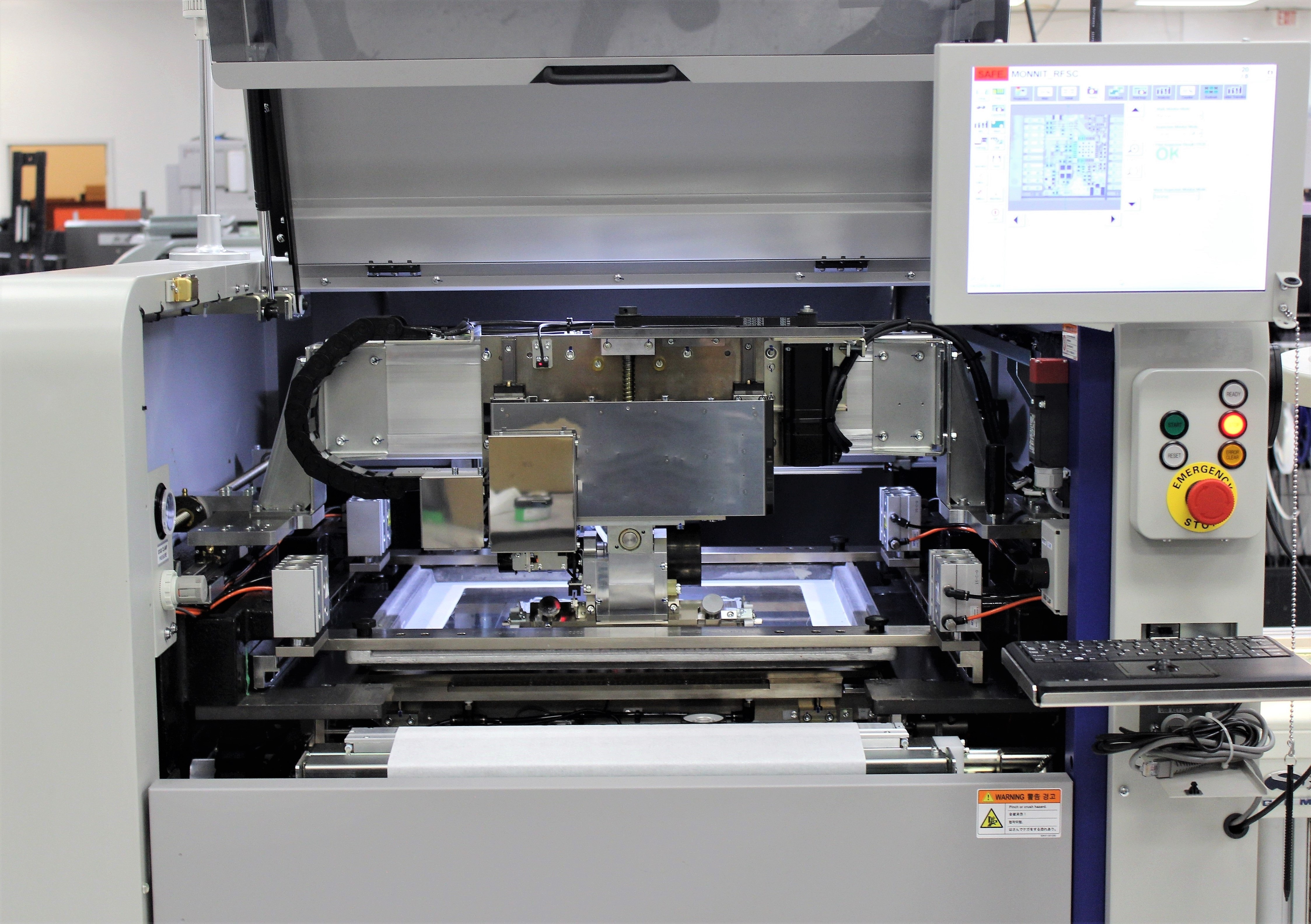

Newonics has years of experience in SMT. We were the first contract manufacturer in the state of Utah to place BGAs and components as small as 0201. To date we have placed hundreds of thousands of BGAs. Our SMT lines use modern up to date equipment built by some of the best names in the industry. We use DEK printers, Philips/Assembleon placement machines and Vitronics-Soltec Ovens.

We pride ourselves in having the most experienced staff and the best SMT expertise in the state. Our process engineers thoroughly review every new product and routinely identify issues before manufacturing, saving our customers time and expensive rework. We quickly diagnose and correct problems and provide feedback to our customers on manufacturing issues. All oven profiles are saved and 100 percent of all boards are inspected by AOI. When the product merits it, 100 percent X-Ray and visual inspection are also performed. We work closely with our customers to fine tune the manufacturing of their products. We encourage our customers to be present when new products are run and first articles are tested and approved.