Thru Hole

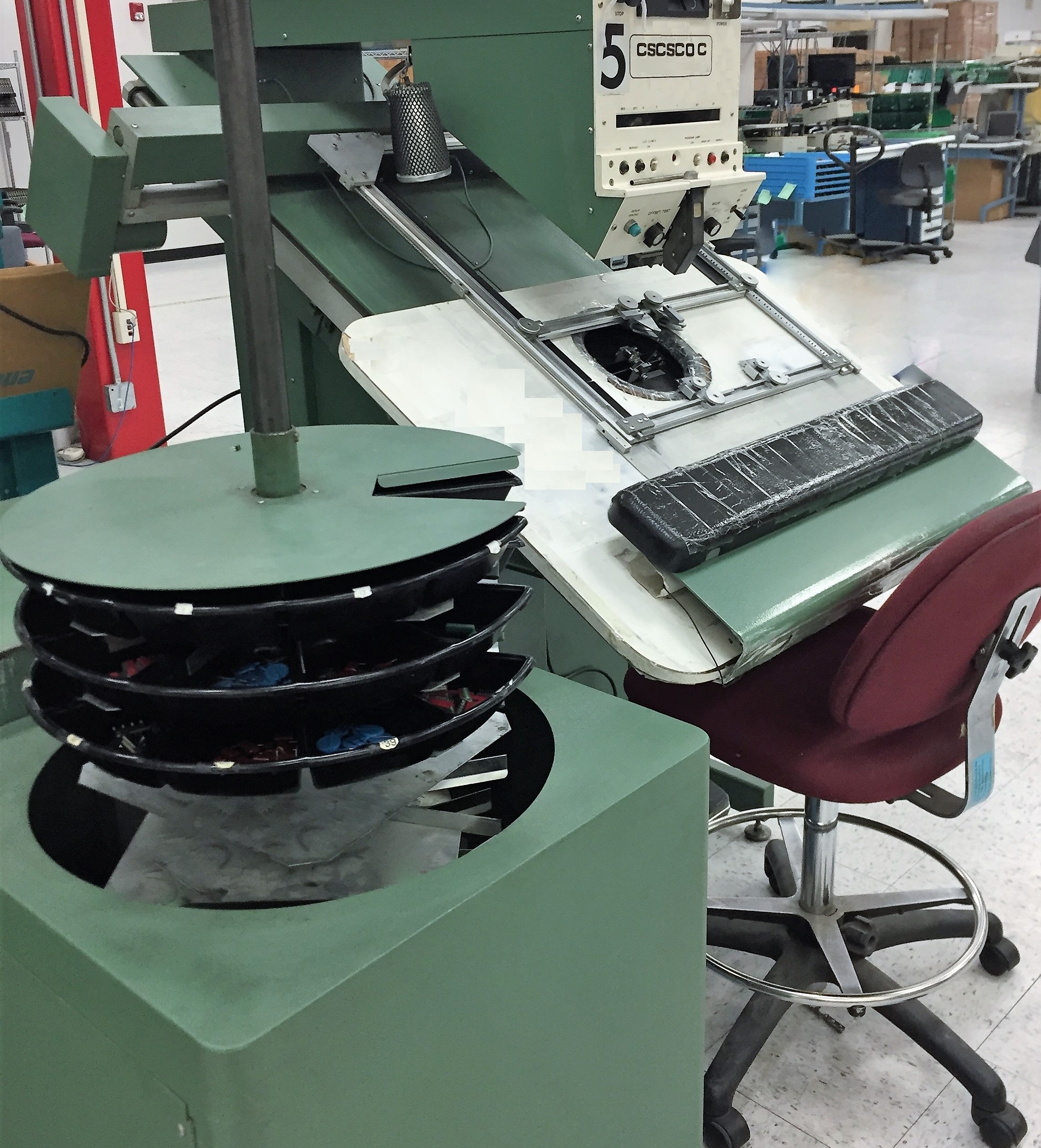

For thru hole placement, we use Contact Systems CS-4000 semi-automatic insertion machines. These machines feed the operator the proper component, identify the proper placement location and polarity, and then cut and clench the leads. This process greatly reduces the chances of human error. Components not suited for these machines are placed in continuous slide lines.

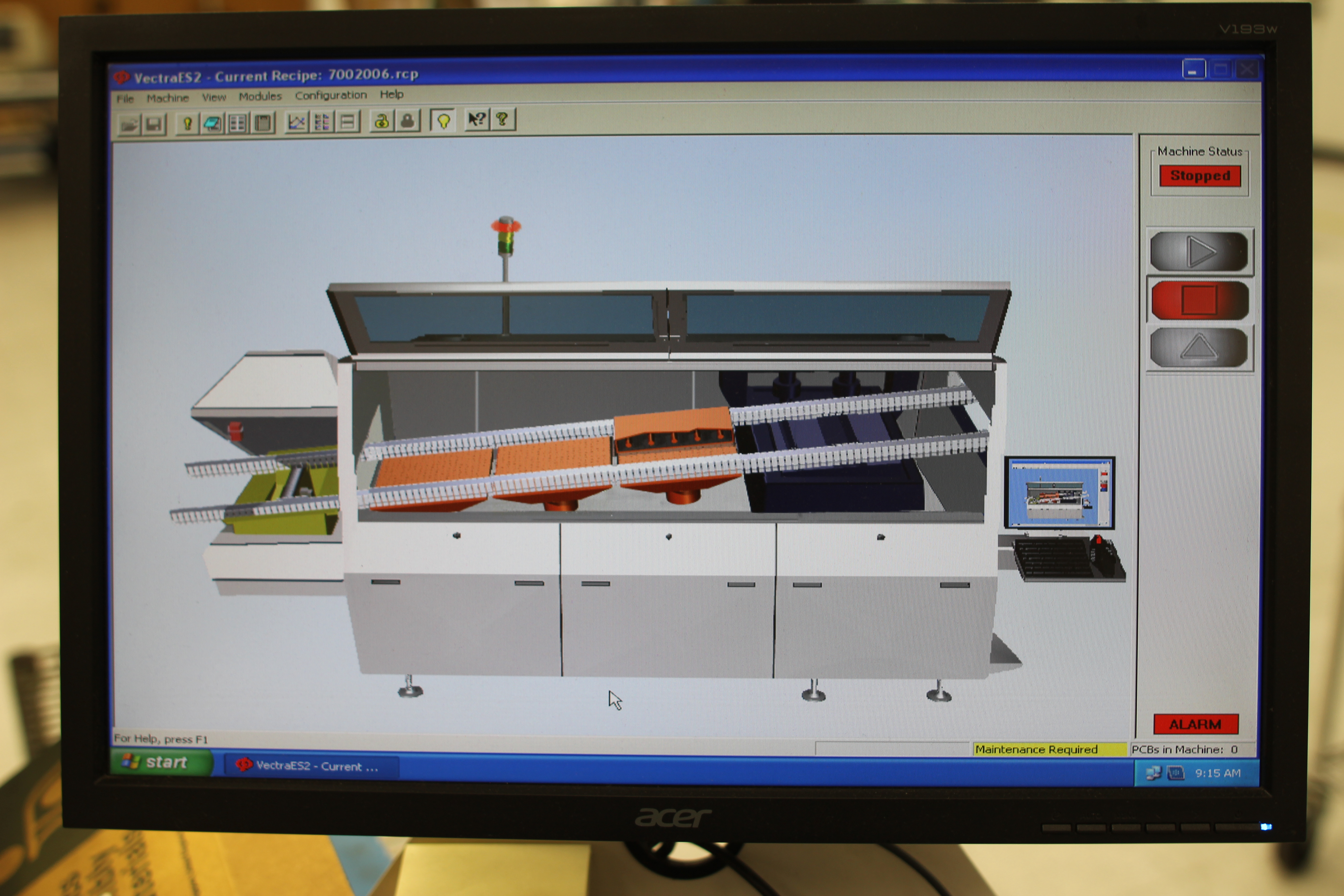

We have dedicated flow solder machines for both RoHS compliant lead free soldering and traditional leaded solders. For boards with surface mount components on both sides and also needing thru hole components, we use selective solder pallets whenever possible eliminating the need for costly hand soldering.

Hand Solder

We use IPC-A-610 as our quality standard. Boards are normally worked to Class 2 and we are capable of Class 3 requirements. Newonics employs the best solder technicians in the state. Many of them have been with us for 5 to 10 years. Our highest level solder technicians are capable of touching up components as small as 0201 or building complete quick turn prototypes including soldering all fine pitch and leadless components. With over fifteen qualified solder technicians, using the newest tools available, we are able to handle both RoHS compliant and traditional soldering requirements.

Test

We are accustomed to working with many customer defined testing setups including full functional, bed of nail, PC driven and RF input and output control. Requirements for serialization, programming, product yield analysis, lot and test documentation traceability, etc, are all available services to our customers.

We utilize personnel with experience to ensure that tests are setup and documented correctly and carried out with consistency.